The steel industry is currently one of the highest carbon emitters, accounting for 7% of all emissions globally. While SSAB is already one of the world’s most efficient steelmakers, we know that the industry still has a long way to go. Our objective is to lead the steel industry to a decarbonized future.

The largest carbon footprint for a new bucket comes from producing the steel.

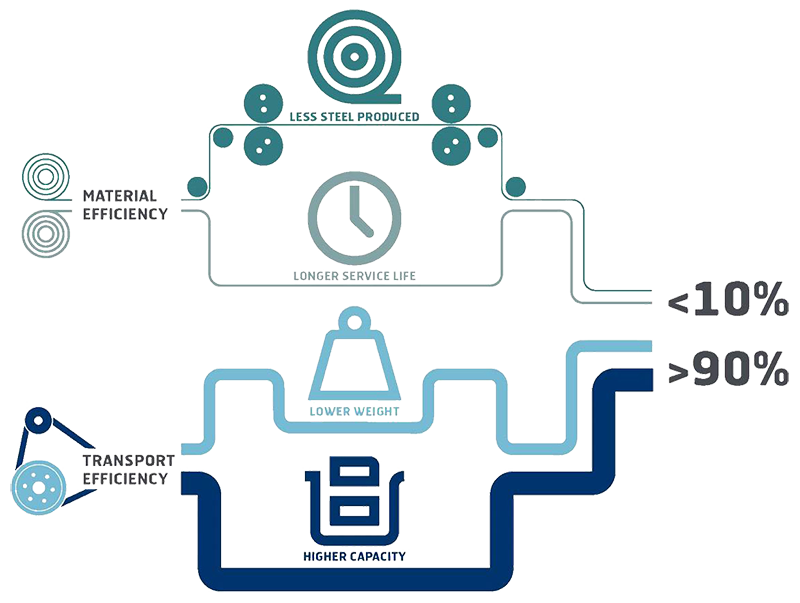

A bucket’s carbon footprint can be reduced in several ways:

- Using higher performing steel, and thus less steel

- Using steel with lower or zero carbon emissions

- Developing a bucket with higher productivity

- Developing a bucket with longer lifetime

What is carbon footprint?

Carbon footprint is a measure of the total greenhouse gas (GHG) emissions caused by an individual, organization, service or product. It's measured as metric tonnes of CO2 equivalent (CO2e) per defined function or unit.

When calculating and reporting carbon footprint, there are established Life Cycle Assessment (LCA) and Environmental Product Declarations (EPD) standards.

Carbon footprint is a product specific, measurable and end-customer relevant measure, just as other product performance data. It is also increasingly more requested by specifiers and end-users.

How to save carbon emissions

A bucket’s carbon footprint can be reduced in several ways.

With wear-resistant, high-strength steel, less steel is needed, resulting in a lower embedded carbon footprint from the steel production. In addition, a steel with lower or zero carbon emissions cut the carbon emission further. SSAB has already one of the world’s most efficient steelmakers, and products with zero-emission steels.

Longer service life

Wear-resistant steel combined with good structural design, make the bucket to last longer. If the lifetime is doubled, embedded carbon emissions over the product lifecycle is only half.

Lower weight

With lower weight, the wheel loader or excavator will need less fuel for the same work. Every 1000 liters of diesel not used saves 3 tonnes of CO2.

Finally, a bucket design with higher productivity and a longer lifetime results in a lower carbon footprint to move the same amount of bulk material.

Higher capacity

When a bucket is lighter, its payload can be increased, resulting in fewer swings for the same material moved. Every present of increased load capacity results in the same percentage of fuel and carbon emission savings.

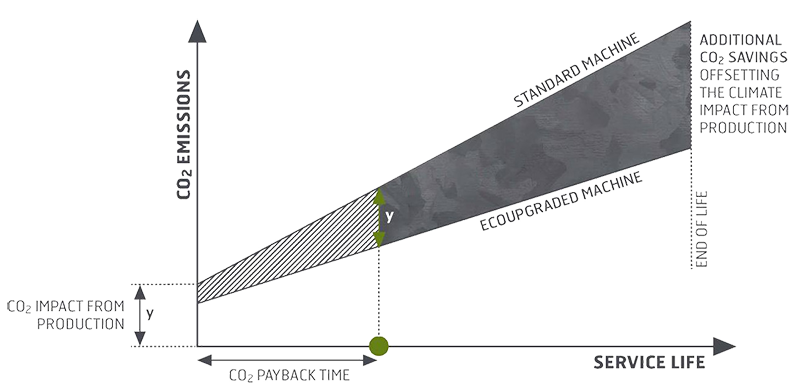

Carbon emission payback time

By upgrading to advanced wear-resistant steel, it will be possible to quickly compensate for the carbon emissions from steel production during the use of the product. And once the break-even point has been reached, the application will continue to deliver carbon savings amounting to many times the original carbon debt.

The carbon emission payback time for a bucket is the time until the CO2 savings during the use-phase of the excavator or loader have become as big as the emission from the steel production of the upgraded bucket.

How much is 100 tonnes of CO₂?

To illustrate the saving or elimination of CO2, we can use cars as a reference.

As an example, a lifetime saving of 100 metric tonnes CO2, corresponds to taking 47 cars off the road for one year.

This calculation is based on the average CO2 emission of Swedish passenger cars in 2017. This average is 2.13 metric tonnes of CO2 per car and year.

Sources: Swedish Environmental Protection Agency and Statistics Sweden.

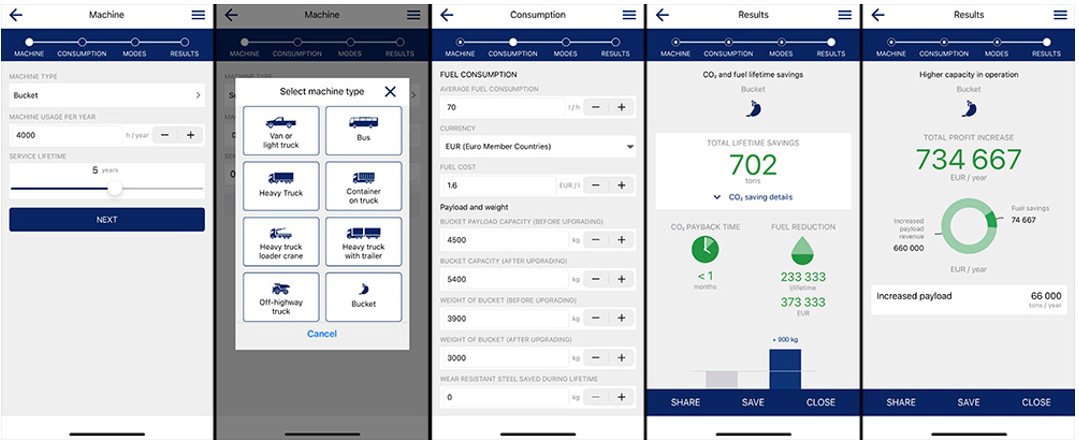

SSAB EcoUpgraded mobile app

With the SSAB EcoUpgraded app, you can calculate how much the upgrading to high-strength steels reduces the weight of equipment, improves fuel economy and increases product lifetime – all of which reduce the carbon footprint.

Download the app

Open App Store (iPhone, iPad) or Google Play (Android phones and tablets). Search for ”EcoUpgraded”, select ”SSAB EcoUpgraded” and download.

Register

When installed, open the app. Write your business email address, name and company. Change to your business email app. Find the email ”SSAB Mobile support”. Scroll down and click on ”Confirm Your Email”. Now, open the SSAB EcoUpgraded app again. Click on “Complete verification”. You are ready to use it!

Choose ”New Calculation”. Next time, you can choose a saved calculation.

Choose bucket, and a typical machine annual usage hours and bucket lifetime data. Adjust the proposed fuel and weight data.

| Input | Example (Metric) | Example (Imperial) | Comments | ||

| Machine usage per year | 4000 | hours/year | 4000 | hours/year | Operation time per year |

| Service lifetime | 5 | years | 5 | years | The total number of years the bucket is in use before end-of-life |

| Fuel consumption, average | 70 | litres/hour | 18 | gallons/hour | Average fuel consumption for the machine |

| Currency | EUR | USD | Choose your currency | ||

| Fuel cost | 1.6 | EUR/litre | 3.2 | USD/gallon | Average fuel cost |

| Bucket payload capacity (before upgrading) | 4500 | kg | 9900 | lbs | Maximum load capacity of the bucket, before upgrading |

| Bucket payload (after upgrading) | 5400 | kg | 11900 | lbs | Maximum load capacity of the bucket, after upgrading. Normally the weight saving through upgrading will increase the load capacity of the bucket with the same amount |

| Weight of bucket (before upgrading) | 3900 | kg | 8600 | lbs | The total weight of the original bucket, before upgrading |

| Weight of bucket (after upgrading) | 3000 | kg | 6600 | lbs | The total weight of the upgraded bucket, after upgrading |

| Wear resistant steel saved during lifetime | 0 | kg | 0 | lbs | It is applicable only for buckets that consume wear steel during its lifetime. |

Results

The results can be presented in three different ways:

- CO2 and fuel lifetime savings: The combined savings from less steel produced, longer service life, less fuel consumed and higher capacity.

- Savings in operation: We assume that a specific total load should to be moved over the life time of the vehicle. This can be done with fewer passes, since the bucket can carry more load each pass. The cost savings include less fuel used, less vehicle maintenance needed as well as lower cost for the operator.

- Higher capacity in operations: We assume that we continue to run the machine full time with the extra load capacity of the bucket. This means that for the same time period more load will be moved. The revenue increase due to the additional load moved, with the same cost for vehicle maintenance and for the operator.

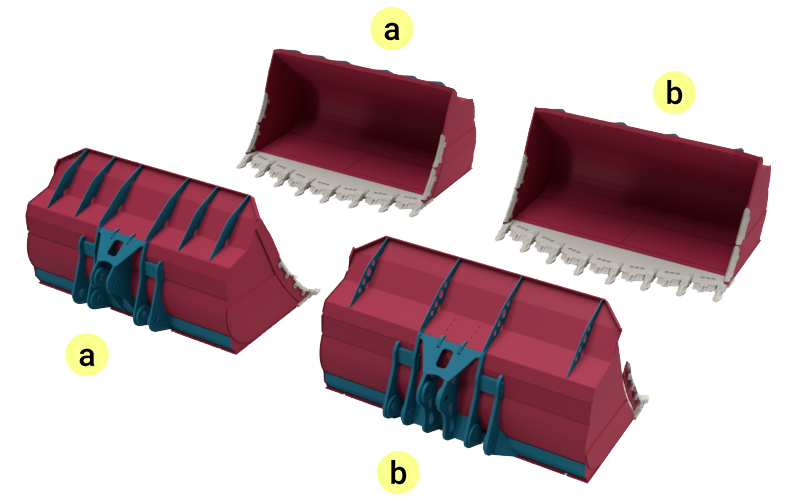

Carbon footprint of a wheel loader bucket

This wheel loader bucket has been upgraded from Hardox® 450 to Hardox® 500 Tuf with improved design, making the bucket volume fit for an increased load capacity corresponding to the reduced bucket weight. Additionally, the new bucket can have a longer lifetime than the original one. The calculation was made with SSAB EcoUpgraded.

a) Previous design b) Upgraded design

Calculation data

Bucket model: Fronteq Eslöv Loader Bucket

Machine class: 35 tonne wheel loader

Diesel consumption, average: 40 litres/hour (assumption)

Machine usage per year: 4 000 hours/year

Design service lifetime: 3 years

Bucket volume: 11 m3 (SAE 1:2)

Weight of bucket (before upgrading): 7 256 kg

Weight of bucket (after upgrading): 6 286 kg (-970 kg or -13%)

Bucket payload capacity (before upgrading): 17 600 kg

Bucket capacity (after upgrading): 18 570 kg (+970 kg or +6%)

Carbon emission savings

Total lifetime CO2 savings: 77 tonnes (1.9 tonnes from less steel produced and 75 tonnes from higher load capacity)

Fuel reduction: 25 073 litres during lifetime (3 years). Corresponding to 40 116 EUR (at 1.6 EUR/litre).

CO2 payback time: 6 months.

Higher capacity in operation

If the extra capacity is used to run the loader machine more for higher revenue, assuming a masses moved revenue of 10 EUR/tonne, 4 000 tonnes moved per day and 330 days in operation per year:

Total profit increase: 740 873 EUR/year (with 72 750 tonnes extra massed moved per year).

The information in this report is only applicable to SSAB’s products and should not be applied to any other products than original SSAB products.

This report provides general results and recommendations for SSAB steel products. This report is subject to SSAB’s Terms of Use. It shall be the user's responsibility to verify that the information contained herein is correct and is suitable to be used for the particular purpose and application of the user. The report is intended to be used by professional users only who possess adequate expertise, qualification and knowledge for the safe and correct use of the results and recommendations in this report. This report is provided “as is”. The use of the report is at user’s own discretion and risk and that users will be solely responsible for any use of this report. SSAB disclaims any liability for the content or potential errors of this report, including but not limited to warranties and condition of merchantability or fitness for a particular purpose or suitability for individual applications. SSAB shall not be liable for any kind of direct or indirect damages and/or costs related to or arising therefrom, whether special, incidental, consequential or directly or indirectly related to the use of, or the inability to use, the report or the content, information or results included therein.