Combination of corrosive and abrasive wear

In a typical situation when hauling gravel or rocks, a harder plate will make the best choice when it comes to fighting wear. However, sometimes the load is corrosive in addition to being abrasive, making the picture much more complicated. The steel’s surface will start to oxidize in the presence of highly corrosive environments, and wear will increase several times over when the abrasive material wears on the oxide layer. Studies on wear in sea water have indicated that material loss can be up to 10 times higher. The level of corrosion depends on the temperature, type of acid, chlorides and surface roughness, among other parameters.

Hardox® HiAce in tipper bodies

For several years, SSAB has been conducting research on wear corrosion and has developed a special steel grade more suitable for these environments, called Hardox® HiAce.

Hardox® HiAce has the same properties as Hardox® 450 but is specially designed to fight wear in corrosive environments, such as municipal waste management, waste in energy plants and in other industries that are sensitive to corrosion.

Read more about Hardox® HiAce.

Wear corrosion tests

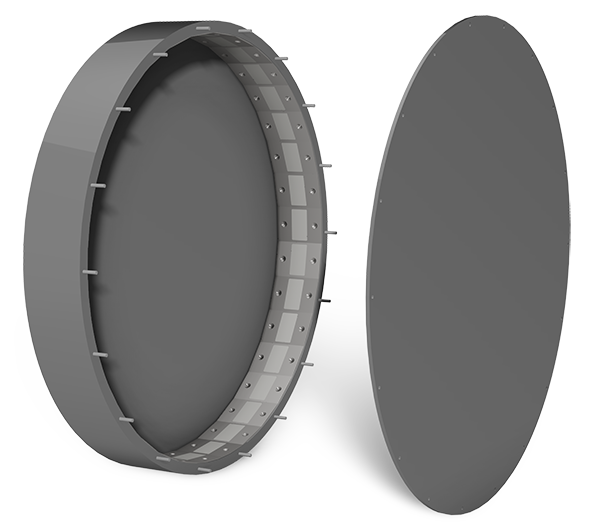

To evaluate the performance of different Hardox® grades, SSAB conducted wear tests with the addition of acetic acids to simulate household waste and other acid abrasive materials. The testing equipment consists of a drum machine with a diameter of 800 mm (31.5”). The drum houses 34 individual samples.

The drum wear test machine for 34 individual samples.

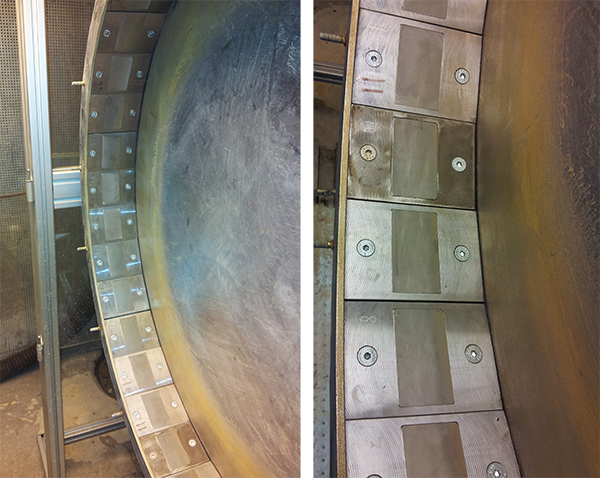

Inside the drum.

The drum was loaded with abrasive materials and liquid, and the samples were weighed both before and after the test to measure the weight loss of each sample. The run time was around 90 hours and the abrasive material was changed twice a day.

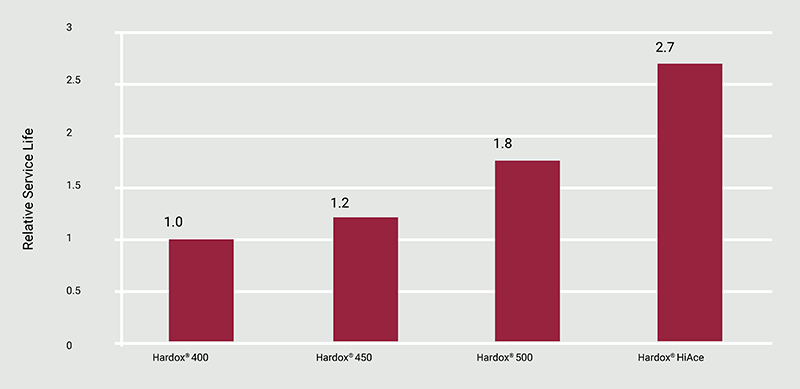

The weight loss of all the samples was then recalculated in order to calculate service life relative to Hardox® 450.

Relative service life based on material loss in the test drum.

The information in this report is only applicable to SSAB’s products and should not be applied to any other products than original SSAB products.

This report provides general results and recommendations for SSAB steel products. This report is subject to SSAB’s Terms of Use. It shall be the user's responsibility to verify that the information contained herein is correct and is suitable to be used for the particular purpose and application of the user. The report is intended to be used by professional users only who possess adequate expertise, qualification and knowledge for the safe and correct use of the results and recommendations in this report. This report is provided “as is”. The use of the report is at user’s own discretion and risk and that users will be solely responsible for any use of this report. SSAB disclaims any liability for the content or potential errors of this report, including but not limited to warranties and condition of merchantability or fitness for a particular purpose or suitability for individual applications. SSAB shall not be liable for any kind of direct or indirect damages and/or costs related to or arising therefrom, whether special, incidental, consequential or directly or indirectly related to the use of, or the inability to use, the report or the content, information or results included therein.