1. What is steel?

Steel is a metallic alloy made primarily from iron and carbon, with small amounts of other elements such as manganese, nickel and boron. The properties of steel can be modified through various heat treatment processes and the addition of different alloying elements. Steel is known for its strength, durability and versatility, and is used in a wide range of applications, including; construction, transportation, machinery and appliances.

2. How is steel made step by step?

The raw material for steel is iron ore and/or recycled steel scrap. The molten iron, which is produced in a blast furnace (BF) or electric arc furnace (EAF), is purified in a converter. The required alloying elements are added in the secondary metallurgy. Finally, the steel is cast into slabs, which are then rolled and heat treated. Before delivery, the material can be leveled, blasted, galvanized, metal and color coated.

4. How do the material properties change after forming?

5. What is the tensile test for steel?

Tensile testing is one of the best-known tests for steel and can be defined by standard EN 10002. Controlled displacement is applied on a standard specimen. The relation between load and elongation is recorded and used to determine a number of material properties, e.g. yield strength and tensile strength.

6. What is the yield strength and the tensile strength of steel?

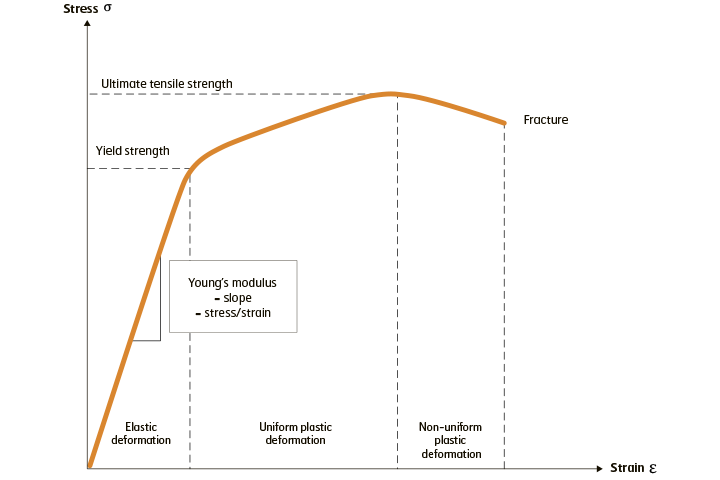

Yield strength is the maximum stress level that steel can withstand before plastic deformation occurs. Above this stress level, steel will no longer return to its initial dimensions or shape. Ultimate tensile strength is the stress level where the load is at a maximum during tensile testing and using the original cross section area.

7. What is the stress-strain curve for steel?

The stress-strain curve for steel shows the relationship between applied load and elongation during tensile testing. It is used to determine mechanical properties of the material, including modulus of elasticity, yield strength, and ultimate tensile strength. The load values are transformed into stress values and the elongation is transformed into strain, resulting in a curve that provides important information on how the material behaves under different loading conditions.

8. What is yield ratio in steel?

9. What is the difference between MPa and ksi?

10. What is the Young's modulus of steel?

11. What is the difference between steel stiffness and strength?

Stiffness is the ability of the material to resist elastic deformation, which is closely related to the modulus of elasticity. Strength is the ability to resist plastic deformation or failure. The stiffness and load carrying capacity of a real structure (e.g. a car body) are also determined by its geometry.

12. Is steel isotropic or anisotropic?

An isotropic material exhibits uniform properties in all directions. For most engineering aspects, steels are isotropic but there are some exceptions. For further details, please contact SSAB Technical Support.

13. What are the thermal properties of steel?

14. What temperature is too cold or hot for steel?

All steels become brittle at some low temperature, and they will lose their mechanical properties at some elevated temperature. The limiting temperatures are steel grade specific. Most SSAB steels are suitable for working at a temperature range of about -40 to +200⁰C. Contact SSAB Technical Support.

15. How is steel tempered?

In the tempering process, a previously hardened steel is usually heated to a temperature (based on the required properties) below the lower critical temperature (A1, ~700⁰C) and cooled at a suitable rate, primarily to increase ductility and toughness, and to relieve quenching stresses. SSAB does not generally recommend tempering. For further details, please contact SSAB Technical Support.

16. How is steel annealed?

Annealing is a generic term for a treatment consisting of heating the steel to and maintaining it at a proper temperature (usually above A1), followed by cooling at a suitable rate (based on the type of annealing). This treatment is performed to primarily soften the steel. SSAB does not generally recommend annealing. For further details, please contact SSAB Technical Support.

17. What is Poisson's ratio for steel?

18. Is steel magnetic?

19. How many different types of steel are there?

20. What are the residual elements of steel?

A residual element in steel is an element not wanted, but cannot be eliminate in the steel-making process. An element can be an intentional alloying element in one grade and residual element in another grade. In general, the residual elements are coming from the input raw materials as iron ore or recycled steel scrap. The content of the unwanted residual elements in SSAB plates is always lower than the critical levels.

The information in this report is only applicable to SSAB’s products and should not be applied to any other products than original SSAB products.

This report provides general results and recommendations for SSAB steel products. This report is subject to SSAB’s Terms of Use. It shall be the user's responsibility to verify that the information contained herein is correct and is suitable to be used for the particular purpose and application of the user. The report is intended to be used by professional users only who possess adequate expertise, qualification and knowledge for the safe and correct use of the results and recommendations in this report. This report is provided “as is”. The use of the report is at user’s own discretion and risk and that users will be solely responsible for any use of this report. SSAB disclaims any liability for the content or potential errors of this report, including but not limited to warranties and condition of merchantability or fitness for a particular purpose or suitability for individual applications. SSAB shall not be liable for any kind of direct or indirect damages and/or costs related to or arising therefrom, whether special, incidental, consequential or directly or indirectly related to the use of, or the inability to use, the report or the content, information or results included therein.