Trailers of today have inherited the traditional chassis design from the first antique carts that was pulled by oxen or horses about 4.000 years ago. It is natural to think that new production techniques and more advanced materials would have promoted new design concepts for a product that has virtually remained unchanged since then, but it is only in the last 150 years steel was used in the vehicle structures and only about 30 years since advanced high strength steel (AHSS) was introduced. For modern vehicles invented during the 20th century, like the automobile and the airplane, a much faster development has occurred to improve design and reduce the weight promoted by mass production, demand for better performance or very high operational cost.

Greater trailer capacity

The requirements for trailers are constantly evolving, with the three main goals being:

- Greater trailer capacity.

- Lower lifetime cost.

- Lower carbon footprint.

Although these goals may sound contradictory, less and more advanced steel can support them all. Together, they ensure that trailers are competitive, profitable and future-proof.

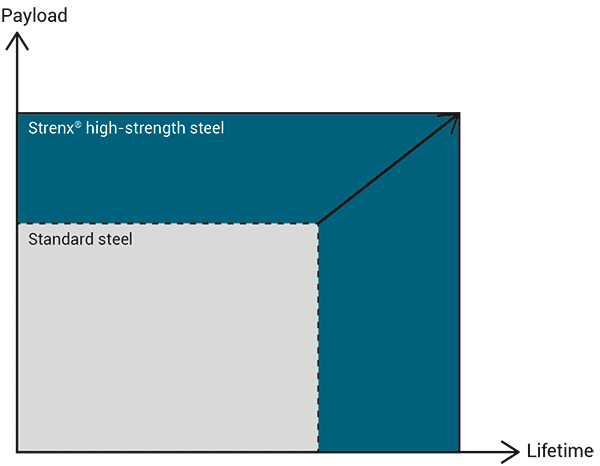

Regardless of whether the limiting capacity is maximum trailer weight or maximum volume, higher trailer capacity is defined by design.

To increase the load capacity, the trailer must be made lighter. To increase the volume capacity, the trailer chassis height can be lowered, assuming the maximum vehicle height is reached.

In both cases, the key is advanced design and advanced steel. For more than 30 years, SSAB has been providing technical support to customers who want to build advanced structural equipment made with yield strengths ranging from 700 to 1100 MPa.

New design aims to go beyond what others have done. To challenge the traditional two-beam trailer solution with perpendicular profiles. To en-able the design to follow and manage the stresses rather than isolate and concentrate them.

A complete redesign is required to achieve the full effect. In addition to redesigning beams and crossbeams, it should include:

- Consideration of alternative production methods.

- Allowing for elastic movements.

- Using alternative joint methods to welding, such as bolting, riveting, clinching and bonding.

- Eliminating welded joints with forming or3D-printing.

- Replacing welded joints.

- Post-treating welded joints.

- Avoiding instability of the steel members.

- Avoiding instability of the whole trailer.

- Avoiding fatigue.

Let SSAB show you how it can be done!

Upgrading from standard steel to Strenx® high-strength steel enables new trailer designs with less steel in the chassis, higher pay-load, greater profitability and a longer service life (illustrative).

Lower lifetime cost

Efficient production methods are key to reducing lifetime costs. Less steel is used, which results in reduced weight, higher trailer capacity and longer service life. Again, advanced design and advanced steel are required.

SSAB’s high-strength steel is highly uniform and consistent. The plates have a very low variation in yield strength, high flatness and a very precise thickness. This results in consistent production conditions, both within a single steel plate and from plate to plate. This is essential for fully automatic laser cutting machines, on-line geometry machine feedback, high-speed manufacturing with machine learning, robot production with 3D scanner feedback and 3D robot forming. The technology is available for serial production. The most successful trailer producers will implement and improve this technology further.

The advanced design also reduces fatigue and results in a longer service life.

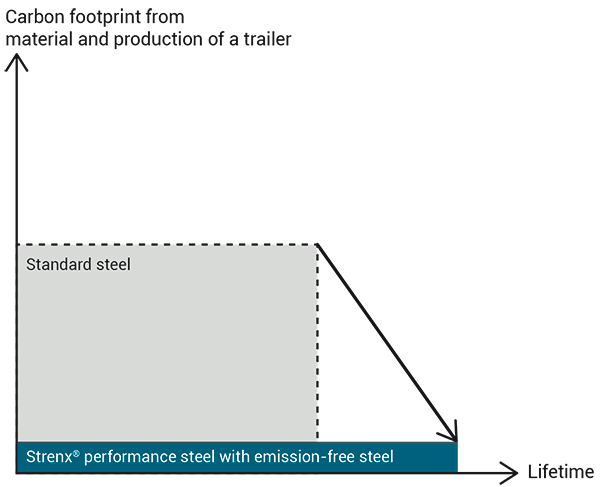

Lower carbon footprint

Eliminating CO2 gas emissions is critical to slowing global warming. The electric, biofuel and low-emission trucks of the future will produce very low carbon emissions during operation.

The large lifetime emissions are caused by the embodied carbon footprint – the emissions from the extraction and transportation of raw materials in the truck and trailer. For a trailer, more than 70–90% of this footprint comes from steel.

To minimize your carbon footprint, there are three steps you can take:

1. Use better steel

SSAB’s blast furnace-based production is among the most CO2-efficient in the world, reducing the carbon footprint of our own products as well as those of our customers. This gives both us and our customers a competitive advantage. On ssab.com, you can download our environmental product declarations (EPD).

2. Use steel better

SSAB is the world leader in high-strength steel. Stronger steel saves weight. This means lighter trailers and stronger products, which in turn reduces the impact on the environment.

3. Go emission-free

SSAB is the world’s leading steel producer of emission-free steel. SSAB Zero™ is a steel made from recycled steel and produces largely zero carbon emissions during steel production, without mass allocation of emission reductions or carbon offsets. SSAB Fossil-Free™ steel is manufactured using revolutionary HYBRIT® technology, which replaces coal with hydrogen in the iron ore reduction process. The byproduct of this process is water instead of carbon dioxide. Find out more about how the groundbreaking technology was developed, how it works, the benefits of fossil-free SSAB steel and why it is a sustainable steel at www.fossilfreesteel.com.

SSAB is happy to support you in calculating your carbon footprint and be your discussion partner in developing a future-proof business.

The steel material and production of the trailer are the pre-dominant sources of carbon footprint. Upgrading from standard steel to Strenx® high-strength steel with SSAB Zero™ or SSAB Fossil-free™ steel enables a very low carbon footprint (illustrative).

The information in this report is only applicable to SSAB’s products and should not be applied to any other products than original SSAB products.

This report provides general results and recommendations for SSAB steel products. This report is subject to SSAB’s Terms of Use. It shall be the user's responsibility to verify that the information contained herein is correct and is suitable to be used for the particular purpose and application of the user. The report is intended to be used by professional users only who possess adequate expertise, qualification and knowledge for the safe and correct use of the results and recommendations in this report. This report is provided “as is”. The use of the report is at user’s own discretion and risk and that users will be solely responsible for any use of this report. SSAB disclaims any liability for the content or potential errors of this report, including but not limited to warranties and condition of merchantability or fitness for a particular purpose or suitability for individual applications. SSAB shall not be liable for any kind of direct or indirect damages and/or costs related to or arising therefrom, whether special, incidental, consequential or directly or indirectly related to the use of, or the inability to use, the report or the content, information or results included therein.