Car bumpers: AHSS steels reduce weight, increase crash performance

Bumper systems for vehicles can leverage advanced- and ultra-high strength steels to both meet enhanced safety standards and lightweighting goals.

Bumper systems for vehicles can leverage advanced- and ultra-high strength steels to both meet enhanced safety standards and lightweighting goals.

With the stick-in concept, the anchor plate of the crash box (can) is eliminated to save bumper system weight while achieving the required crash performance.

Car bumper OEMs are realizing weight savings by eliminating the anchor plate of the crush box (or “crush can”) and instead “sticking” the boxes into the rails. The boxes are then screw fastened in the Y direction. In one example, eliminating the two anchor plates reduced the weight of the entire front bumper system by 2.5 kg. Suggested steel grades for the crash box include Docol® HR800CP or Docol® CR800DP.

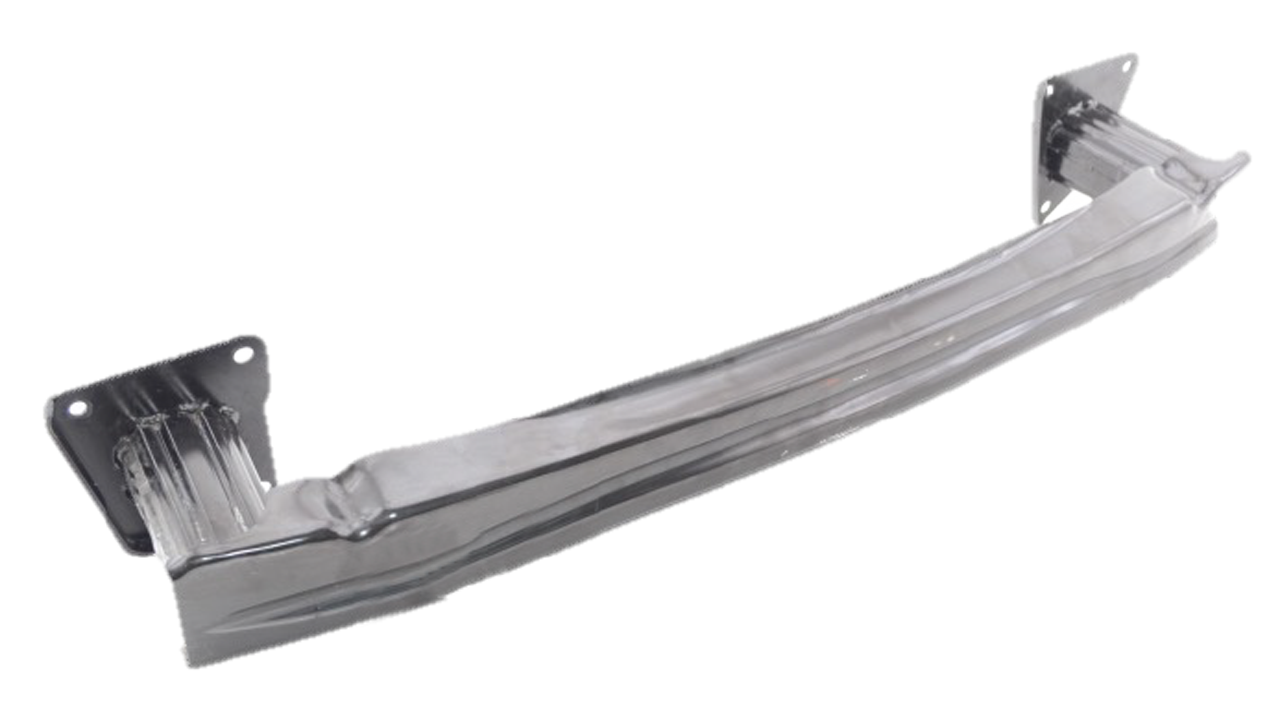

End profile of the roll formed, laser welded and 3D bent bumper beam in Docol® CR1500 martensitic.

Need to meet low-speed crash tests with a lighter weight bumper system? Consider this example, where a CR1300 Martensitic bumper beam was upgraded to Docol® CR1500M. The 1.0 mm thick 1500 MPa martensitic beam was roll formed, laser welded, and then 3D bent. The results are a cost-efficient improvement to crash performances – at a reduced weight.

This bumper beam, made in Docol® PHS 2000, reduced the weight of the bumper system by 17%.

By increasing the strength of the bumper beam from PHS 1500 MPa to Docol® PHS 2000, this bumper manufacturer realized a 17% weight reduction – making it lighter than more costly aluminum. The new PHS 2000 bumper beam helped the auto OEM meet both fuel and emissions requirements.

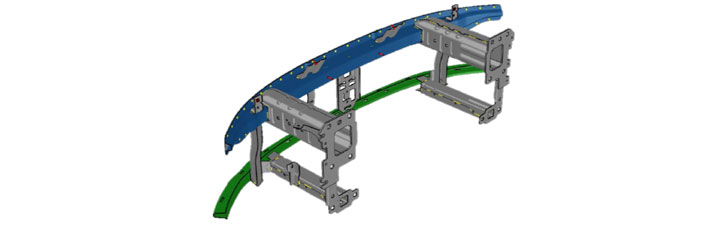

The blue indicates Docol® CR 1000DP bumper beam, while the green is the Docol® 800DP lower load path crossmember.

Looking for additional cost and weight savings in your bumper system? Consider high-strength, cold-formed steel options. In this example, a bumper beam’s PHS 1500 MPa steel was replaced with Docol® CR 1000DP, eliminating the expensive and time-consuming hot-forming process.

Interface plate / Anchor plate / Back plate: Docol® HR420LA – Docol® HR1000CP

Crash box: Docol® HR CP 800, Docol® HR DP 800

Bumper / Cross beam: Docol® CR CP 1180, Docol® CR MS 1500-1700, Docol® PHS 2000 (uncoated)

In just one to two weeks, you can get trial samples of most of our commercially available AHSS/UHSS steel grades – plus some of our newest, not-yet-released steels.

Our steel grades serve specific design purposes and are chosen by designers for a wide range of automotive applications.