Doubling the crash load transfer performance of EV cross members

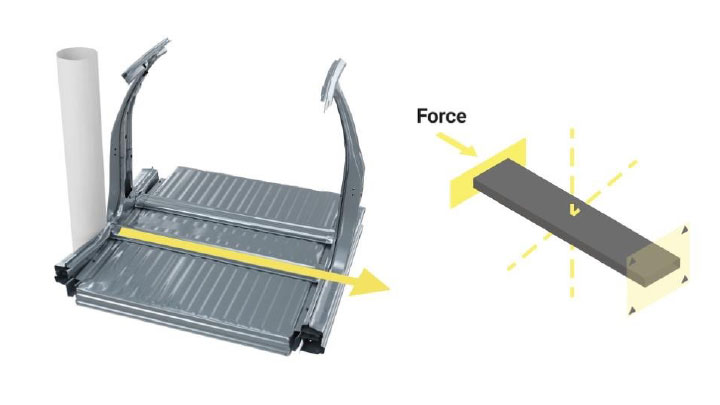

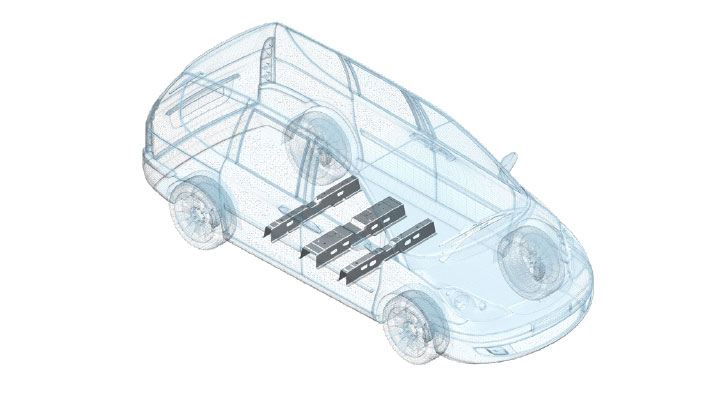

To protect floor-mounted EV battery packs during a side crash, cross members in the passenger compartment should not deform, but instead transfer the force to the opposite side of the car.

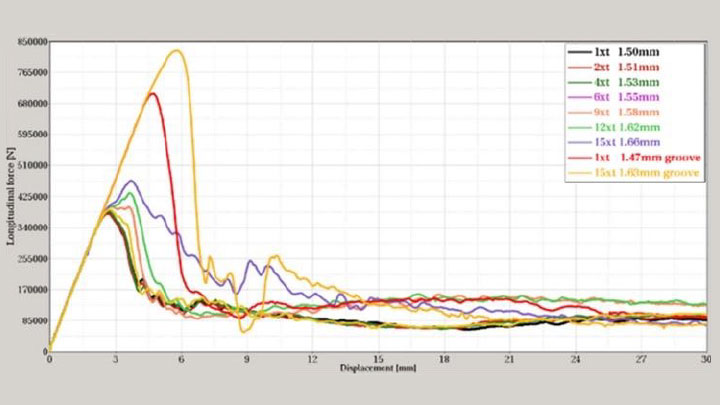

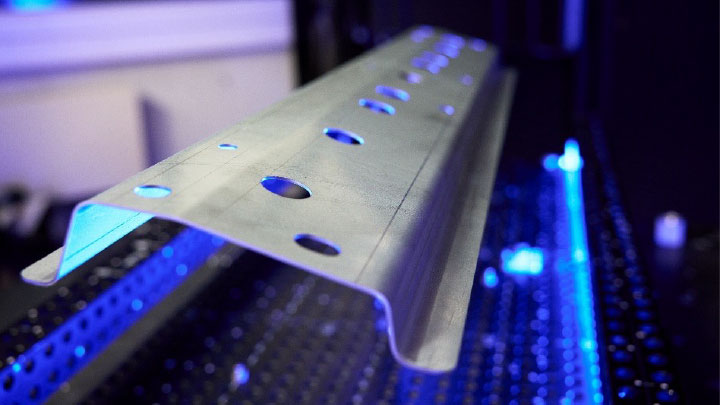

SSAB simulation for Docol® 1700 martensitic steel cross members show that a profile with a 15xt (radii in mm times thickness of the cross member) performs better than 1xt, with material thickness adjusted so the overall weight of the different profiles are the same.

An optimized cross member can more than double the crash load transfer performance over a square-shaped profile. To see the profiles of the cross member beams tested here, including the best performing profile, contact Docol.