Car seat frames and tracks made lighter, stronger, more durable

Car seat frames and tracks are taking advantage of higher strength steels to reduce weight and wall thicknesses while increasing strength and durability.

Car seat frames and tracks are taking advantage of higher strength steels to reduce weight and wall thicknesses while increasing strength and durability.

Backrest side members can be made thinner and lighter when formed from Docol® 1000DP.

Going from 800 dual phase steel to Docol® 1000DP meant this car seat OEM could reduce the backrest side member to just 0.8 mm thickness, reducing weight and materials.

Car seat tracks in Docol® CR1000DP provide increased static performance and brinelling resistance.

Upgrading from HR 500 LA steel to Docol® CR1000DP in 1.6 mm thickness meant this Tier 1 car seat supplier could reduce the weight of its seat tracks by 25%. Plus, the new UHSS steel improves both the static performance and the brinelling resistance, increasing the car seat tracks’ durability.

Rear seat frame made with Docol® 1000DP tubes deliver 40% lighter performance.

For the frame of this rear car seat, switching from HC420LA steel to Docol® 1000 dual phase steel enabled a reduction in tube wall thickness, from 2 mm to 1.2 mm, reducing the weight from 3 kg to 1.8 kg – making it 40% lighter.

Docol® 800DP tube and Docol® Roll 1000 for the rear tube and side member frame, respectively.

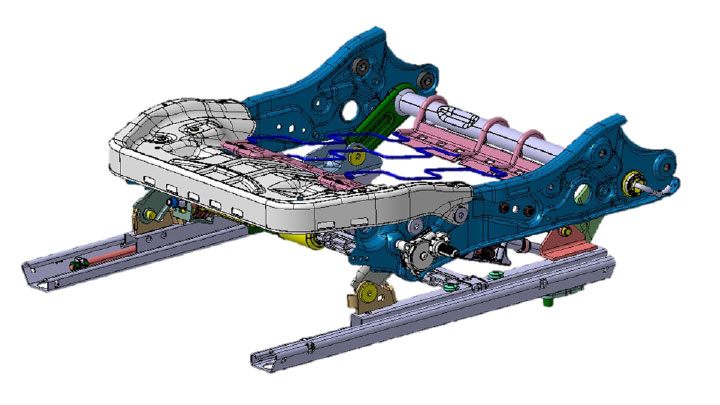

This new design for a car seat bottom frame leveraged the light weight of both Docol® 800DP tube for the rear member and Docol® Roll 1000 for the cushion side member frame. Starting a new design with Docol® AHSS or UHSS steels is a strong way to position your car seat frames ahead of the competition.

This car seat track replaced the more expensive re-rolled steel with Docol® 800LA in 1.64 mm and 1.90 mm thicknesses.

The manufacturer of car seat tracks replaced costly re-rolled steel with Docol® 800LA in 1.64 mm and 1.90 mm thicknesses. Docol® advanced high strength steels have the potential to reduce costs throughout your car seat frame and track construction.

Docol® HR 355HE to 550HE grades help semi-fine blanking operations achieve intricate shapes that are virtually free of micro-cracks.

The semi-fine blanking operations used to form conventional hot-rolled steels into gears and other car seat recliner mechanisms are known to cause edge cracking, leading to higher scrap rates. SSAB developed High Edge (HE) Ductility grades to virtually eliminate these micro-cracks.

Headrest tube: Tubes, Docol CR 600-800 DP

Upper cross member: Docol CR 800-1000 DP

Lower cross member: Docol CR 1000 DP

Rear tube: Tubes, Docol CR 600-800 DP

Seat pan: Docol CR 340-420 LA, Docol FORM 04 (CR4)

Seat track: Docol CR 800-1000 DP, Docol CR 800-1000 CP, Docol CR 800 LA

Cushion side member: Docol CR 800-1000 DP, Docol CR 800-1000 CP

Recliner: Docol HR 700 LA, Docol HR 800-1000 CP

Backrest side member: Docol CR 800-1000 DP, Docol CR 800-1000 CP

In just one to two weeks, you can get trial samples of most of our commercially available AHSS/UHSS steel grades – plus some of our newest, not-yet-released steels.

Our steel grades serve specific design purposes and are chosen by designers for a wide range of automotive applications.