Hardox® 400

Hardox® 400 is an all-around steel that resists wear and abrasion with a nominal hardness of 400 HBW. Thanks to its high toughness, bendability and weldability, it’s well suited for equipment exposed to moderate wear applications.

What is Hardox® 400?

Hardox® 400 is a trusted steel in the Hardox® wear plate family, with a heritage of hardness and toughness going all the way back to 1974, when Hardox® was launched as the world’s first bendable wear steel. This allowed for reliable performance both in the workshop and in operation. Plates in Hardox® 400 come in thicknesses from 2 to 130 mm (0.079 to 5.118”). This grade is also available as pipes or tubes and round bars.

I’m interested, contact me

Hardox® 400 leaves mild steel behind

Mild steel just doesn’t cut it in today’s equipment. It’s not strong enough, or hard enough to deliver the productivity or service life you expect. When you upgrade from steels such as S255, S355, A36, grade 50 or A514, SS400 or S45C to Hardox® 400, you can look forward to stronger and lighter equipment with higher capacity and less maintenance. And you can cut, weld and machine Hardox® 400 using standard techniques and tools. All in all, Hardox® 400 outperforms mild steel, every time.

Hardox® 400 makes friends in the workshop

Hardox® 400 is as easy for fabricators to work as any mild steel. There are several reasons: The steel is very clean and has consistent properties, meaning it behaves in a predictable way every time. It also has a lean chemical composition, which gives it excellent welding properties.

Hardox® 400 can be bent with tight bending radiuses, which sets Hardox® steel apart from other AR steels.

Get free technical advice

Predictable in welding

Welding of Hardox® 400 is performed with similar welding consumables as for mild steel, without any specific requirements. There is no need for preheating for thicknesses up to 20 mm (0.787”), and any standard welding technique can be used. You can download our welding brochure for more information.

Welding of Hardox®

Ready for machining

Any type of machining can be performed with ordinary workshop equipment, such as the common radial drilling machine for drilling and countersinking of Hardox® 400. As always, you can get technical support and advice from our local technical development managers. We also have a brochure on best practices when machining Hardox® wear plate.

Machining recommendations for Hardox®

Where is Hardox® 400 used?

Hardox® is a versatile wear steel that’s found in applications practically everywhere, in equipment for roadbuilding, construction, agriculture, quarrying, mining, recycling, cement and concrete production, and more. The steel’s wear performance and toughness in combination with its workshop-friendliness makes Hardox® 400 an industry legend.

Are you missing out on longer wear life?

As you probably know there are successors to Hardox® 400 in the Hardox® range. After all, it’s been around for well over 40 years. However, you may not be aware of how much you can gain by upgrading to a newer model of Hardox® wear plate. The numbers are impressive.

Calculations with the Hardox® WearCalc app show:

- A 30-40% increase in wear life when using Hardox® 450 with 50 extra HBW compared to Hardox® 400.

- A 80-100% increase in wear life when using Hardox® 500 Tuf with 100 HBW higher hardness compared to Hardox® 400.

Hardox® 400 – not your average AR 400 steel

When comparing AR steels, just looking at the hardness doesn’t tell the full story – far from it. Hardox® 400 has a guaranteed through-thickness hardness, a result of the carefully controlled quenching and tempering process at the steel mill. Your benefit? You get reliable and predictable wear performance over the steel’s service life.

Hardox® 400 is also covered by guarantees for thickness, flatness and bending performance. The consistency of these properties ensures predictable processing in the workshop. Every plate you get will behave as the previous one. No surprises, and that’s a good thing for every production manager.

Download Hardox® Guarantees here

MB Crusher’s bucket adds value on site thanks to Hardox® 400

MB Crusher from Italy makes its crusher buckets in Hardox® 400 and gains both productivity and reliability in the toughest crushing operations with concrete and rocks.

Read more about MB Crusher

Concrete truck mixer lasts longer with Hardox® 400

Stetter in Germany uses Hardox® 400 and Hardox® 500 to reduce weight in its concrete mixer drums and make room for more concrete.

Read more about StetterFind your nearest Hardox® 400 supplier

Hardox® 400 wear steel has local availability on a worldwide scale. The most common Hardox® grades and dimensions can be delivered to you directly from an SSAB mill or from nearby SSAB stocks in less than 48 hours. Hardox® Wearparts, our worldwide network of wear service centers, can make your wear parts for you in Hardox® 400 or other Hardox® grades.

Find your local Hardox® 400 supplier

Dimension Range

Hardox® 400 is available as plate in thicknesses of 4.0 – 130 mm (5/32 - 5.12”), and as sheet in thicknesses of 2.0 - 8.0 mm (0.079 - 0.315”). Hardox® 400 plate is available in widths up to 3350 mm (131.89”) and lengths up to 14630 mm (575.98”). Hardox® 400 sheet is available in widths up to 1650 mm (64.96”) and lengths up to 16000 mm (629.92”). More detailed information on dimensions is provided in the dimension program.

Mechanical Properties

(mmin)

(HBW)

(MPaksi), not guaranteed

(mmin)

(HBW)

(MPaksi), not guaranteed

1) Brinell hardness, HBW, according to EN ISO 6506-1, on a milled surface 0.5 – 3 mm below surface. At least one test specimen per heat and 40 tons. The nominal thickness of supplied plates will not deviate more than +/- 15 mm from the thickness of the test specimen used for hardness testing. For sheet the Brinell hardness test is according to EN ISO 6506-1 on each heat treatment individual/coil. Hardness is measured on a milled surface 0.3 - 2 mm below surface.

2) Hardness test is not performed or guaranteed for Hardox® products with thicknesses < 2.5 mm. The tabulated hardness values for thickness < 2.5 mm is a conversion from the tensile strength.

For more information please see the datasheet 2067- Hardness conversion of thin Hardox® wear sheet.

The nominal thickness of supplied plates will not deviate more than +/- 15 mm from the thickness of the test specimen used for hardness testing.

Hardox® wear plate is through-hardened. Minimum core hardness is 90 % of the guaranteed minimum hardness.

Impact Properties

Charpy V 10x10 mm test specimen 1)

1) Impact toughness measured upon agreement. For thicknesses between 3 mm and 11.9 mm, sub-size Charpy V-specimens are used. Impact testing according to ISO EN 148 per heat and thickness group. Average of three tests.

2) Typical value for 20 mm.

Chemical Composition (heat analysis)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

The steel is grain refined. *) Intentional alloying elements.

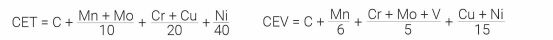

Carbon Equivalent CET(CEV)

Thickness

Tolerances according to Hardox® Thickness Guarantee.

Hardox® Guarantees meet the requirements of EN 10029 Class A for plate, but offer more narrow tolerances. For sheets the guarantees meets the requirements of 1/2 EN 10051.

Length and Width

According to SSAB’s dimension program. For plate, the tolerances are according to SSAB´s mill edge standard or tolerances that conform to EN 10029. For sheet the tolerances conform to EN 10051, tighter tolerances available on request.

Shape

Tolerances according to EN 10029 for plate and according to EN 10051 for sheet.

Flatness

Tolerances are according to Hardox® Flatness Guarantees Class C for plate, which are more restrictive than EN 10029. For sheet, the tolerances are according to Hardox® Flatness Guarantees Class A, that offer narrower tolerances compared to EN 10051.

Surface Properties

According to EN 10163-2 Class A, Subclass 1.

Delivery Conditions

The delivery condition is Quenched or Quenched and Tempered. Plates are delivered with sheared or thermally cut edges and thicknesses over 80 mm are delivered with mill edge as standard. Sheets are delivered with an as-rolled surface and mill edge as standard.

Fabrication and Other Recommendations

Welding, bending and machining

Recommendations can be found in SSABs brochures at www.hardox.com or consult Tech Support.

Bendability for plate are according to Hardox® Bending Guarantees Class D. For sheet, the bendability are according to Hardox® Bending Guarantees Class A.

Hardox® wear plate is not intended for further heat treatment. It has obtained its mechanical properties by quenching and when necessary by means of subsequent tempering. The properties of the delivery condition cannot be retained after exposure to temperatures in excess of 250ºC .

Appropriate health and safety precautions must be taken when welding, cutting, grinding or otherwise working on this product. Grinding, especially of primer coated plates, may produce dust with a high particle concentration.