General Product Description

The high-strength structural steel at 650 MPa

Strenx® 650MC D/E is a hot-rolled structural steel made for cold forming, with a minimum yield strength of 650 MPa for stronger and lighter structures. Strenx® 650MC D/E meets or exceeds the requirements of S650MC in EN 10149-2.

Typical applications include a wide range of components and parts, such as demanding load-bearing structures. Strenx® 650MC D/E comes in coils, slit coils or cut-to-length sheets.

Mechanical Properties

(mmin)

(mmin)

(min MPaksi)

(MPaksi)

(min %)

(min %)

(mmin)

(mmin)

(min MPaksi)

(MPaksi)

(min %)

(min %)

(mmin)

(mmin)

(min MPaksi)

(MPaksi)

(min %)

(min %)

The mechanical properties are tested in the longitudinal direction.

1) If ReH is not applicable then Rp0.2 is used. On thicknesses >8 mm the minimum yield strength may be 20 MPa lower.

2) A80 value applies for thicknesses < 3.00 mm.

3) A5 value applies for thicknesses ≥ 3.00 mm.

4) For both longitudinal and transverse direction.

Impact Properties

Charpy V 10x10 mm test specimen 1)

Charpy V 10x10 mm test specimen 1)

1) Impact testing according to EN ISO 148-1 is performed on thicknesses ≥ 6mm. The specified minimum value corresponds to a full-size specimen.

Chemical Composition (ladle analysis)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

1) If the material is to be hot-dip galvanized according to category A or category B in EN 10149-2 this must be specified at the time of order.Other galvanizing classes with higher Si-content are available after agreement.

2) Sum of Nb, V and Ti = max 0.22%.

The steel is grain refined.

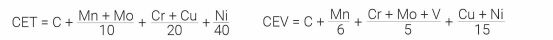

Carbon Equivalent CET(CEV)

Thickness

Tolerances according to Strenx® Thickness Guarantee.

Strenx® Guarantees offer considerably narrower thickness tolerances compared to EN 10051.

Length and Width

Width and length tolerances according to SSAB standard.

SSAB standard offer narrower width and length tolerances compared to EN 10051.

Length tolerances only apply for cut to length sheets.

Shape

Tolerances according to EN 10051. Narrower tolerances according to the SSAB standard are available on request.

Flatness

Tolerances according to Strenx® Flatness Guarantee Class A.

Strenx® Flatness Guarantee offer narrower tolerances compared to EN 10051.

Flatness guarantees only apply for cut to length sheets.

Surface Properties

According to EN 10163-2 Class A, Subclass 3.

Delivery Conditions

Thermomechanically Rolled. Strenx® 650MC D/E is available in as rolled or pickled surface condition with mill or cut edge.

Delivery requirements can be found in SSAB’s brochure Strenx® Guarantees or on www.ssab.com.

Fabrication and Other Recommendations

Welding, bending and machining

Strenx® 650MC D/E has good welding, cold forming and cutting performance.

Strenx® 650MC D/E is a cold forming steel not suited for heat treatments at temperatures above 580°C since the material then may lose its guaranteed properties.

For information concerning fabrication, see SSAB´s brochures on www.ssab.com or consult Tech Support.

Appropriate health and safety precautions must be taken when bending, welding, cutting, grinding or otherwise working on the products.

Show specs in:

Ready to upgrade?

You can improve the performance and reduce the weight of your equipment by upgrading from Strenx® 650MC to Strenx® 700MC. Using a steel with 8% higher yield strength means you can increase the equipment’s load-bearing capacity. Get in touch with our steel specialists at SSAB Tech Support or SSAB Knowledge Service Center for an update on upgrading.