General Product Description

Strenx® Tube 700QLH is plasma-welded, quenched and tempered hollow section with a minimum yield strength of 700 MPa.

Its high strength, combined with naturally stiff form of the welded hollow section, enables construction of stronger and lighter structures. Strenx® Tube 700QLH meets or exceeds the requirements of EN 10210-3:2020.

Typical applications are load-bearing lattice structures in the lifting, material handling and transportation sectors, especially in conditions where extremely good toughness is needed.

Dimension Range

Circular Dimensions

Mechanical Properties

Strenx® Tube 700QLH

(min MPaksi)

(MPaksi)

(min %)

Mechanical properties meet the requirements of prEN 10210 (2016).

Impact Properties

Charpy V 10x10 mm test specimen 1)

1) Impact testing according to EN ISO 148-1 is performed on thicknesses ≥ 6 mm. The specified minimum value corresponds to a full-size specimen.

Chemical Composition (ladle analysis)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

In addition, boron (B), molybdenum (Mo), nickel (Ni) or copper (Cu) may be used as alloying elements either singly or in combination.

The steel is grain refined.

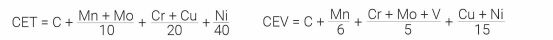

Carbon Equivalent CET(CEV)

Tolerance Circular

1) All external dimensions are measured with a minimum distance from the end of the section. The distance must be a minimum of 100 mm.

Delivery Conditions

The tubes are plasma welded quenched and tempered.

Show specs in: